Inductor burnout for many reasons, here to share the failure because the design of the margin deficiency result in inductor coil short in circuit, then leads to the user’s property and personal loss.

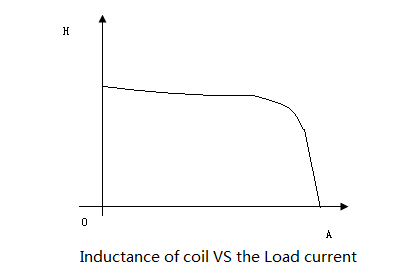

According to the characteristics of the magnetic components, the relationship between the inductance of the inductor and the load current is shown in the following figure 1 :

Figure 1 inductance and load current curve of inductance coil

As the load current increases, the current flowing through the inductor coil increases, and the inductance begins to decrease when the certain current is reached. This is due to magnetic saturation, resulting in smaller inductance reactance. Due to the load voltages remains unchanged, leading to a sharp current rise through the inductor coil, and cause coil burned out.

The root cause of failure, from circuit design , the maximum loading of inductor coil can withstand is not fully considered, as well as the saturation current of the inductor. According to P=UI, the power consumption of the inductor can be calculated by the maximum saturation current; and the current flow through the inductor of normal working condition should not exceed 70% of the value of the saturation current.

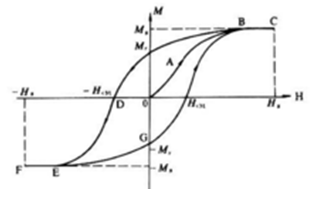

From the inductor coil supplier, mainly due to the design of the margin is insufficient, and cause the magnetic core has entered the saturation state. According to the hysteresis loop characteristics of the magnetic core, as shown in figure 2:

Figure 2 hysteresis loop soft magnetic material

For the design of inductor coil, it is necessary to take the saturation of the magnetic core into account, otherwise the inductor will enter the saturation state. Such as the use of high permeability magnetic core (magnetic material), with the less number of turns high inductance and high Q value can be obtained, the manufacturer can save manufacturing cost; but the high permeability magnetic core enter the saturation state with light loading current.

The improved measures can be taken, increase the air gap of the core , contrast to no air gap, therefore reducing the permeability to increase the saturation current. If there is a gap , can use a low initial permeability of core material, increase the number of turns of the inductor and meet the requirements of saturation. Of course, trade-off between Rdc and manufacturability should be considered.